Troopy Build Series: Water System Design and Install

Dedicated Water System – Why?

The reason we travel by vehicle and overland is to be able to reach places that are remote and often not seen by many. One of the aspects of travelling this way we love is the ability to be independent, one of the challenges of this is finding and storing clean water to allow our independence.

In previous vehicles, we have always had a limitation on how much water we could physically carry due to the practical aspects of storing water in jerry cans and other containers around the vehicle.

One of the main reasons for choosing and building a 78-Series Troopy was the ability to configure the vehicle to be more like a camper van, with amenities like water and a shower. It was the requirement to have an on-board shower that led to the need to install the Drifta Gullwing window and the Alu-Cab shower cube (awning).

Troopy Water System

- Dedicated Water System – Why?

- Water System Overview

- How the Water System Works

- Duoetto MK2 Electric 10L Storage Water Heater

- SEAFLO 21 Series DC Water Pump (SFDP1-010-040-21)

- Long Range Automotive – 90 Litre Water Tank

- John Guest 12mm Push-Fit System

- Conclusion – Is a self-contained water system worth it?

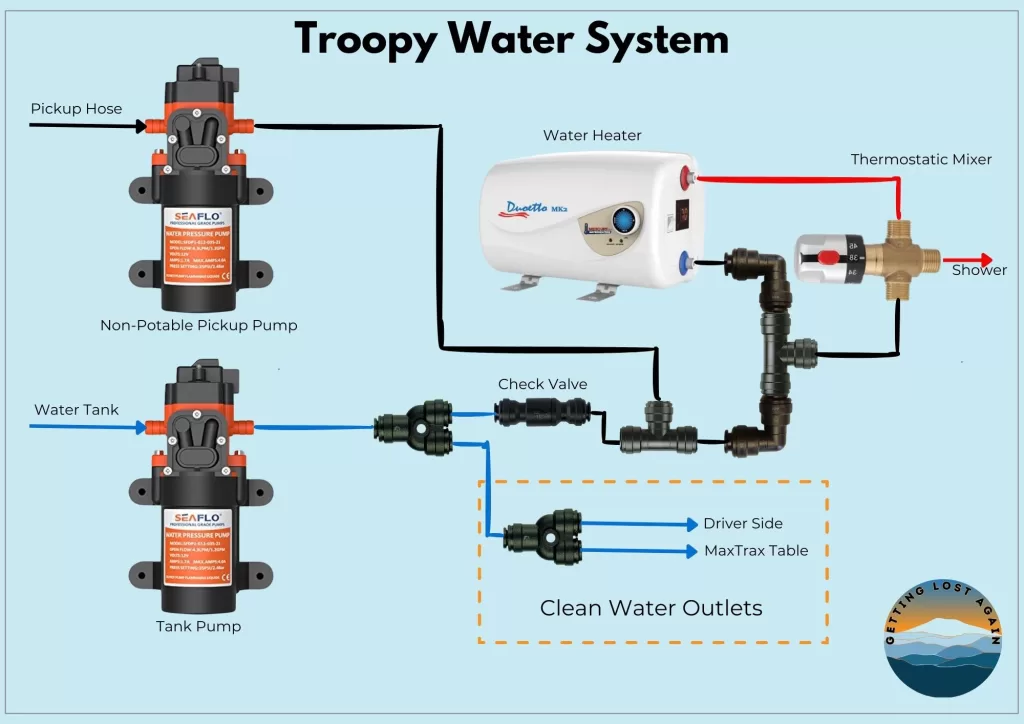

The design of the water system not only allows for the storage of 90 liters of potable (drinking) water, and hot showers but also the ability to use clean, but non-potable water sources for showering, without contaminating the potable water storage tank or circuits. For example from a river or stream water using a pick-up hose.

In our build, we have designed the water system around a 90-litre underslung tank, which is mounted forward of the rear axle and central to the vehicle. This will still allow us to upgrade the rear fuel tank to a larger tank in the future if we need further fuel range. The tank we are using is from Long Range Automotive (LRA) in Lilydale, Victoria.

In this post, we’ll go through the whole system including explaining how it works, a schematic diagram of the water system, where we installed it and what components we used.

Water System Overview

Requirements for Our System

Before we get into what we built, here are the key functions or requirements we wanted to be able to achieve from our water system.

- Ability to have a shower, ideally warm, without carrying gas.

- Ability to store significant water, which depending on climate could last up to 7 days.

- Ability to use other sources of water to shower should we have the opportunity to conserve potable water.

- Ability to filter incoming water to the tank.

- Easy maintenance, should we have a pump failure or a leak! This also means components should be readily available.

We aimed for a system that’s both reliable and efficient. Here’s the breakdown:

- Water Storage: 90-Litre Long Range Automotive Stainless Steel tank

- Pumps: Two Seaflo pumps (SFDP1-010-040-21) – one for the main drinking water from the tank and one for non-potable sources. Having two pumps means that should one fail we could swap them around.

- Water Heater: AusJ Duoetto 10L 12v/240v water heater for hot showers even when off-grid. The Duoetto has the advantage of both 240v and 12v heating, the 240v heating is quicker because the element is more powerful. So we could for example heat the water before leaving on a journey and top-up/maintain it whilst driving.

- Filtration: B.E.S.T. Inline, model 322H additionally we will be using occasional doses of WaterPure also, should we be in areas where we are unsure of the water quality.

- Tank Guage: RV Electronics LED Tank gauge to show the level of water available in the tank, this is a battery-powered device, which only uses the battery when the button is pressed, so it should last forever!

Taps & Outlets

For the outlets, we chose to make use of the area on the vehicle which is normally used for the vent panels, it is common to swap these for a utility vent/panel cover that allows mounting of accessories, such as Solar or 12V power, water and ARB air fitting for pumping up tyres etc.

In this picture, you can see we have an input for the Solar blanket in the middle two water connections for potable drinking water out and a water pickup on the right.

These Utility Panels are from Mission 4×4 in Western Australia. The doors are pushed to open and close. There are a few other designs out there, which are similar from companies like The Cruiser Company, Unwind Designs/Ark Fabrication, Project Overlander and also from Thornurns.

Taps & Outlets:

- Tank filler – under the bonnet.

- Shower outlet – Front Gullwing Driverside,

- Water pickup and drinking water out – Driverside utility panel,

- Drinking outlet – Passengerside utility panel,

The passenger side utility panel is also from Mission 4×4, this one houses the ARB air coupling, a 12V socket to connect the awning lights to and also a drinking outlet. We have a flexible machinist lubrication hose, which works well in the location as it is in the perfect place for the MaxTrax fold-down table we have mounted on the passenger side, which is also from Mission 4×4.

How the Water System Works

Before getting into the specifics of exactly how we installed the system in the Troopy, let’s take a quick look at how the system works. There are two circuits the primary potable water circuit and the non-potable circuit. The whole system is very simple and meets the basic requirements for our use and would certainly form a good basis for anyone wanting to design their own system.

Primary Circuit – Potable Water

The primary circuit of the water system is used to supply clean drinking water, used for hydration, cooking and general hygiene. Below that is represented by the blue piping and the tank pump.

- Water is sourced from the tank (not shown) via the tank pump

- After the tank pump. There is a 2-way y-splitter that:

- Provides clean water to the outlets on the rear driver’s and passenger sides of the vehicle.

- Sends water to the non-potable shared circuit for showers.

- Isolation between the potable and non-potable circuits is provided by a check (one-way) valve, which prevents non-potable water from entering the potable circuit.

Secondary Circuit – Non-Potable Water

The secondary circuit of the water system is used to clean but not drinkable i.e. non-potable water to be used for showers, the primary intent of this circuit is to conserve, where opportunity allows, the potable drinking water in the under-vehicle tank. For example, you may come across a well on the Conning Stock Route (CSR) which has water that is clean enough for a shower, but you may not want to risk drinking it. This could also be the case for many rivers or creeks etc.

The secondary circuit is represented by the black hose in the diagram above, the red hose represents warm water and in this case, is also non-potable above.

- Water from the non-potable sources utilises the pick-up hose via the non-potable pickup pump in the diagram above.

- The pressurised water is then fed to the Duoetto water heater and the thermostatic (temperature) control valve.

- Hot water is provided to the thermostatic valve via the red hose.

- The thermostatic (temperature) valve will automatically maintain the water at the shower head to a user pre-set temperature, whilst there is sufficient hot water available.

- The shower head is mounted on the Drifta gullwing behind the driver’s door.

- Privacy is provided by the Shower Awning – Alu-Cab Cube.

Want more? Check out this post about our Troopy Overland Build Series

Duoetto MK2 Electric 10L Storage Water Heater

Duoetto MK2 Electric 10L Storage Water Heater by AusJ. This unit is a game-changer, providing hot water using either 12v power from the vehicle or 240v when hooked up. From our tests, even here in the winter water seems to stay warm for well over 24 hours, which suggests that the insulation efficiency of these heaters is good.

| Feature | Specification |

|---|---|

| Capacity | 10 Litres |

| Power Source | 12V DC (Aux/Secondary Vehicle Battery) / 240V AC (Mains Power) |

| Power Consumption | 300W (12V) / 1000W (240V) |

| Current Draw | 25A (12V) / 4.2A (240V) |

| Heating Element | Stainless Steel |

| Tank Material | Stainless Steel |

| Dimensions | 378mm(L) x 275mm(W) x 285mm(H) |

| Weight | 6.5kg |

| Safety Features | Over-temperature Protection, Dry-heating Protection |

| Installation | Vertical Wall Mount |

| Warranty | 2 Years |

| Additional Notes | Energy Efficient, Compact Design |

SEAFLO 21 Series DC Water Pump (SFDP1-010-040-21)

SEAFLO 21 Series DC Diaphragm Pump 12V/24V 2.0-4.3LPM 17-80PSI Water Pump. These pumps are compact, relatively powerful, and known for their durability and “Quiet” operation.

| Feature | Specification |

|---|---|

| Flow Rate | 3.8 LPM 1 GPM |

| Pressure | 40 PSI (2.8 BAR) |

| Voltage | 12V DC |

| Current Draw | 1.6A (Max 4.0A) |

| Port Size | 10mm (3/8″) Hose Barb |

| Self-Priming | Yes |

| Duty Cycle | Intermittent |

| Protection | Ignition Protected |

| Dimensions | 159mm(L) x 97mm(W) x 62mm(H) |

| Weight | 0.8kg |

| Additional Notes | Compact, Quiet Operation* |

Key Seaflo Pump Specifications (SFDP1-010-040-21)

Long Range Automotive – 90 Litre Water Tank

For our main potable water storage, we chose to fit an underslung water tank from Long Range Automotive, they are located in Lilydale, Victoria (Australia). I understand that they ship globally as I have seen their tanks being sold on European 4×4 Overland websites. LRA does aftermarket Fuel and Water tanks for many vehicles, including LandCruiser and the 70-Series, such as the 75, 76, 78 and 79’s. We will soon be getting a larger diesel tank fitted, more on that in the Diesel heater install post.

The tank has a level sensor from RV Electronics and also the Water outlet located at the rear side of the tank.

I chose to insulate the water pipe for two reasons. The first is to protect it and eliminate any noise. The second was to provide some insulation, to help reduce the chance of the pipe freezing.

The wiring and pipe work are routed to the righthand side (driver side) of the vehicle and then over the rear tank, to the driver’s side rear quarter. The water hose goes into a bulkhead John Guest fitting and then up to the pump panel. The sensor wiring goes in through the existing wiring grommet located up there in the rear quarter.

Bonnet – Water Filler and Tank Vent – The water filler and tank vent are located under the bonnet. I chose to locate them there because I did not want to make a large hole in the bodywork for a filler. It is a simple and effective option. Having to open the bonnet to fill the tank will also promote the good habit of looking at the engine bay and checking oil often, to identify issues early.

In order to fit the tank in this area of the vehicle, it is necessary to modify the exhaust. In stock form, the OEM Toyota exhaust manifold gets in the way of the tank. In order to fit the tank, it is essential to fit a straight muffler.

Note: I chose to fit the 2.5″ Torqit aftermarket exhaust system. Which I LRA recommended as working with the tank. Unfortunately, this is not true any more and only the 3.5″ Torqit exhaust works without modification with the tank. I got lucky though and LRA agreed to modify the muffler routing slightly for me Free of Charge as the instructions they had given me had not been updated. I’d highly recommend LRA, they are just a nice bunch of people.

Caution! With the LRA 90L Tank, you need to use the 3.5″ Torqit Exhaust, not the 2.5″ to avoid additional modifications!

John Guest 12mm Push-Fit System

We chose to use the John Guest 12mm push-fit system which offers a quick, reliable, and tool-free way to connect pipes for various plumbing applications, including water systems in vehicles like our Troopy. I liked the simplicity of the system, which made it the obvious choice. Some of the key benefits and features are:

- Ease of Use: Simply push the pipe into the fitting for a secure connection. No special tools or skills are needed.

- Secure & Leak-Proof: The fittings create a strong, watertight seal. Although to be leakproof you do need to make sure that the pipes are fully home.

- Flexibility: The fittings allow for easy disassembly and reconfiguration of the system if needed. This is really handy when you are trying to work out how to lay out your system.

- Durability: The fittings are made from high-quality plastic that is not going to corrode and wear.

John Guest provide a whole host of different building blocks, some manufacturers make compatible components, should you need something that is not in the standard catalogue. We had this with bulkhead fittings to mount the Nito couplings for the external hoses. Here are some of the parts that are standard.

- Straight Connectors: Used to join two lengths of pipe.

- Elbow Connectors: Used to create 90-degree bends in the pipework.

- Tee Connectors: Used to create branches in the pipework.

- Divider (Y Connectors): Used to split/join pipework to/from two branches

- Reducers: Used to connect pipes of different sizes.

- Stop Ends: Used to cap off the ends of pipes.

- Pipe Supports: Used to secure the pipework and prevent sagging.

The main things to watch out for when using the John Guest (JG) system are:

- Cut the Pipe Squarely: Ensure a clean, square cut for a proper seal.

- Push the Pipe Fully In: Make sure the pipe is fully inserted into the fitting until it clicks.

- Use Inserts: Inserts prevent the pipe from deforming either from the cutting process or from heat or bending. Using these ensures that the fit in the push fittings is correct and minimises the chance of leaks.

- Locking clips: John Guest make locking clips that help ensure that the collars on the fittings do not get depressed. They also act as a visual indicator that the joint is sound. Personally I installed these after I checked each joint for leaks as a visual reference for where I have finished work.

- Use the Correct Pipe Size: Ensure the pipe’s outer diameter matches the fitting’s size.

- Avoid over-tightening: Do not overtighten the fittings in hose clamps or supports, as this can damage them.

- John Guest Pipe Cutter: Grab yourself one of the proper pipe cutters, these are cheap and easy to use but offer cheap insurance for ensuring a quality square hose cut.

| Feature | Specification |

|---|---|

| Pipe Size | 12mm Outer Diameter |

| Material | Acetal Copolymer Body, Stainless Steel Collet Teeth, EPDM O-Rings |

| Maximum Pressure | 15 bar (217.5 psi) at 20°C |

| Temperature Range | 0°C to 65°C (32°F to 149°F) |

| Suitable Fluids | Potable Water, Air, and Inert Gases |

| Certifications | WRAS, NSF, KTW, DVGW |

| Connection Type | Push-Fit |

| Disconnection | Simple push-button release |

| Benefits | Quick & Easy Installation, Reliable & Leak-proof, Reusable, Corrosion Resistant |

The Installation Process

It’s hard to define exactly how in a step-by-step form you should install the water system in your camper or 4×4 vehicle, given that almost everyone will be entirely different, with different factors impacting the final design, but what I will show instead is how I installed the system described above in our Troopy.

Before I get into that there are a few factors you should consider before you start throwing stuff in the vehicle.

- Planning & Placement: We carefully thought about where we would put the components of the system so that we not only used the limited space optimally but also made it as easy as possible to get at stuff should we need to change something, for example, a defective water pump.

- Water Heater Mounting: Aside from the main water tank which is mounted under the vehicle, the water heater is a big chunky item. We mounted the water heater in our middle cabinet, where we can keep an eye on it and also get at it as easily as possible should we need to maintain it.

- Plumbing: Running the pipes and connecting everything was the trickiest part. Routing the pipes and minimising joins is the aim, as every joint is a possible leak. We mounted most of the plumbing circuit in the driver’s side rear wing, which is located directly below the water connections in the utility hatch. To enable mounting in the wing, we installed all of the components in replacement wall panels, specifically from Mission 4×4.

- Electrical Connections: The location we chose for the water heater is also in close proximity to the 12v electrical system and lithium batteries. This means the cable run will be as short as possible, minimising the dreaded voltage drop.

- Testing: After fitting everything make sure you test every connection for leaks whilst they are still accessible. I tested stuff at interim stages in the build to give myself reassurance along the way. This did take longer, but I could not bear the thought of having to pull everything apart to fix a leak, which I could have prevented.

Conclusion – Is a self-contained water system worth it?

Our Troopy’s water system is a major upgrade on our previous vehicles, giving us the confidence to tackle longer and more remote adventures. It’s an investment in comfort and self-sufficiency that will pay off every time we hit the tracks. I’d say it is definitely worth it.

Follow along with our build.

- Stay tuned for more Troopy Overland Build updates!

- Have questions about our water system or anything else? Reach out on Instagram

Dan’s a windsurfing, adventure-seeking nomad with a passion for exploring the globe overland and an Engineer. Having grown up in the Middle East, he brings a unique perspective to Getting Lost Again, sharing his love for discovering hidden gems and embracing the unexpected. When he’s not on the road, he finds inspiration in windsurfing and other creative pursuits – and is equally at home under a vehicle solving problems as he is exploring a new place.